Control Centre Design

Our staff have designed and delivered in excess of 150 safety critical control facilities, across industry on a global basis. The design of a control facility is a complex process that forms only a component in the wider system design. Our aim is to provide safe, effective and efficient operations by minimising the potential for human error, increasing the operator’s ability to communicate with his outside environment and to provide a working environment that maximises operator vigilance and alertness.

Our staff have designed and delivered in excess of 150 safety critical control facilities, across industry on a global basis. The design of a control facility is a complex process that forms only a component in the wider system design. Our aim is to provide safe, effective and efficient operations by minimising the potential for human error, increasing the operator’s ability to communicate with his outside environment and to provide a working environment that maximises operator vigilance and alertness.Our strength is that we understand the application of standards such as ISO 11064 and ensure that human behaviour, performance, capabilities and limitations are addressed in the design.

Human Integration Ltd. recognizes that simply following an accepted normative process is not a guarantee of success. Experience in the application of such standards and knowledge of their strengths and weaknesses is essential. The Human Integration Ltd. in-house specialist design experience ensures a genuine integrated process.

All control facilities share a common fact; in that they will be a major safety and business critical investment with a likely 20 to 30 year operational life span. It is important to get it right, first time.

Our experts bring a wealth of experience to your project that will ensure success.

Control Centre Health Check

Our staff have designed and delivered in excess of 150 safety critical control facilities, across industry on a global basis. Our strength is that we fully understand the content and application of standards such as ISO 11064 and ensure that human behaviour, performance, capabilities and limitations are addressed in the design.

Our staff have designed and delivered in excess of 150 safety critical control facilities, across industry on a global basis. Our strength is that we fully understand the content and application of standards such as ISO 11064 and ensure that human behaviour, performance, capabilities and limitations are addressed in the design.

We have a vast experience in the verification and validation of a control centre’s ability to safely and effectively handle all modes of operations including start up, normal operations, maintenance and revision maintenance, process disturbances, safety critical situations and shut down.

We employ structured checklists and processes that are recognised by industry that reference corporate governance, international standards and industry best practice. The process will address the following areas:

• Building Layout and security;

• Equipment layout, inside the control facility

• Console design and layout

• Working Environment;

• Control – and Safety Systems, Man-Machine Interfaces;

• Job Organisation;

• Procedures and Work Description;

• Training and Competence; and

• E-Operations, Remote Operations, Integrated Operations.

Human Integration Ltd. will document the findings and provide a workable improvement plan with recognition to project constraints and processes such as ALARP.

Human Factors and Working Environment in Major Projects

Human Integration Ltd. offers Human Factors and Working Environment expertise to the design of complex socio-technical systems. Our structured approach is aimed at optimizing operational safety, reliability, efficiency and effectiveness.

Human Integration Ltd. offers Human Factors and Working Environment expertise to the design of complex socio-technical systems. Our structured approach is aimed at optimizing operational safety, reliability, efficiency and effectiveness.Having worked across highly regulated safety critical industries on a global basis we have a broad applied experience of regulatory and corporate governance and industry best practice.

We have extensive experience throughout the design life cycle; concept, FEED, detailed engineering, construction and commissioning, working closely with the various engineering disciplines. We provide active input, review and intervention as part of an integrated process that minimizes rework and ensures adherence to schedule. We offer practical solutions to concerns identified and support the design teams through any change process.

In addition we play a key role in the operational and health risk identification and reduction processes employed as the design progresses.

Barrier Safety Management

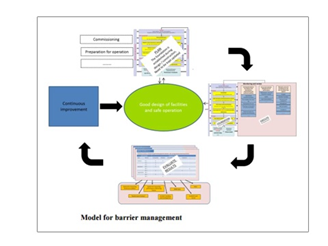

Human Integration Ltd. personnel play an active role in robust Barrier Management Systems with the goal of ensuring barrier effectiveness by identifying and reducing the potential for barrier latent failure resulting from human error. The human performance in barrier effectiveness needs to identified and understood, monitored and managed to reduce the likelihood of a major incident.

Human Integration Ltd. personnel play an active role in robust Barrier Management Systems with the goal of ensuring barrier effectiveness by identifying and reducing the potential for barrier latent failure resulting from human error. The human performance in barrier effectiveness needs to identified and understood, monitored and managed to reduce the likelihood of a major incident.All aspects of the barrier’s design, human-machine interface, operation, maintenance and inspection need to be addressed including:

• Training and competency;

• Accurate indication of need when manually activated;

• Event velocity if manual activation is required;

• Operation procedures (incl. roles and responsibilities);

• Maintenance procedures; and

• Inspection procedures (incl. remote condition based monitoring).

The human performance analyses can be applied during the engineering design process and/ or during operations.

Emergency Operating Procedures, Isolation Systems, Labeling Systems, Permits

15 killed and 180 injured

All Safety Critical Systems must look to reduce human error in their execution by the end user. Human Integration Ltd. specialists have 120 Years of experience working with Safety Critical Systems and are well placed to provide guidance in the development Safety Critical Systems.

Pipeline Safety

The managers and workers of pipelines companies in five different countries have developed a list of the 25 most important Human Factors Issues that pipeline companies face in the design, construction, operation and maintenance of pipelines. Human Integration Ltd personnel were part of this important effort which is documented as follows:

The managers and workers of pipelines companies in five different countries have developed a list of the 25 most important Human Factors Issues that pipeline companies face in the design, construction, operation and maintenance of pipelines. Human Integration Ltd personnel were part of this important effort which is documented as follows:ATTWOOD, D.A. and FRANKLIN-ALDERMAN, C., (2012) “Human Factors Influences on Pipeline Damage Users’ Guide.” Prepared for the Pipelines Research Council International (PRCI).

Since this report was issued, Human Integration Ltd. have turned the 25 pipeline issues recommendations into a series of Gap Analysis questions that will allow pipeline companies to determine how safe and efficient their operations are. The Gap Analysis process can be applied by a dedicated team of specialists who use accepted auditing techniques for evaluation, or by applying the process as an employee questionnaire to obtain first-hand opinion on the health of their companies.

Interested parties are urged to contact Human Integration Ltd. for more information on how this important process can be implemented by your organization.

Valve Operation, Criticality, and Maintenance Access

Human Integration can deliver a process of valve selection and design access that will reduce rework in design, reduce musculoskeletal injury, and lower incidents of rule breaking through proper access and design. Human Integration can deliver a Valve Criticality process that can be customized for client needs and delivered on P&IDs as an extra layer of information for operations and maintenance.

Human Integration Ltd. has developed tools to:

• Assess the musculoskeletal risk associated with manually operating valves;

• Rank the risks (by valve) across an operating facility;

• Develop a list of actions which our clients can realistically address over time

Human Performance in Construction

Human Performance in Construction addresses the hazards associated with construction processes, by identifying and implementing design and procedural solutions (Critical Task Analysis) aimed at the Performance Shaping Factors in the construction industry.

Human Performance in Construction addresses the hazards associated with construction processes, by identifying and implementing design and procedural solutions (Critical Task Analysis) aimed at the Performance Shaping Factors in the construction industry.Construction contingency funds are applied to the construction budget for Human Risk Factors. A Human Factors plan for construction will reduce the level of budget contingencies by using lessons learned and applying HF strategies to reduce the likelihood of human error in construction. Human Integration Ltd. will produce a plan for construction that can reduce accidents, rework in facility construction, and increase productivity on time spent on tools.

Human Factors and Working Environment Design Handbooks

Human Factors (HF) and Working Environment (WE) engineering design handbooks collate the minimum project agreed HF/ WE requirements into a single, readily accessible document. The layout and content are carefully considered to ensure it is readily understood and consistently applied by the various engineering disciplines across the entire design.

Human Factors (HF) and Working Environment (WE) engineering design handbooks collate the minimum project agreed HF/ WE requirements into a single, readily accessible document. The layout and content are carefully considered to ensure it is readily understood and consistently applied by the various engineering disciplines across the entire design.

The correct application of the content is key in ensuring that;

• the design and layout of equipment and workspaces reflect and accommodate tasks to be carried out;

• the design is intuitive to operation and procedure reducing rule breaking;

• the design provides efficient and safe access and manual handling during operation and maintenance under all normal, upset/ emergency and environmental conditions by the full range of potential personnel;

• access and egress is optimised during emergency conditions;

• the design of controls and displays are intuitive to operation;

• working environment area limits are met providing safe working conditions and ensuring that personnel do not exceed occupational exposure limits; and

• the working environment health risks posed are addressed in the design and layout.

Large multi-discipline design teams benefit in a number of ways:

• Reduction in time searching through numerous project specifications and guidelines;

• Reduction in misinterpretation of content and intent;

• Reduction in costly rework and project delay;

• Reduction in review comments; and

• Reduction in design costs.

Human Integration Ltd. have produced and supported the application of these handbooks using a wide range of project, corporate, regulatory, industry bodies, national and international standards and industry best practice. Human Integration Ltd. train the engineering design team in the handbook’s content, purpose and application at the earliest stage in the design process.

Correct and consistent work space design will reduce Error Enforcing Conditions and increase Maintainability and Operability of your facility. Correct and consistent facility design with Human Performance criteria will improve safely, increase efficiency ensuring continuity of operation and reduce OPEX costs over the life cycle of your facility

Signs and Labels

Signs and labels serve two important functions in a process plant. They identify equipment and they instruct workers on the correct methods of operation and maintenance. As such, they help prevent operating and maintenance errors and they serve as a training aid for new workers.

Signs and labels serve two important functions in a process plant. They identify equipment and they instruct workers on the correct methods of operation and maintenance. As such, they help prevent operating and maintenance errors and they serve as a training aid for new workers.Poor signs and labels can promote errors that can lead to accidents and injury. Signage and labeling issues continue to top the list of safety violations published by the US, Occupational Safety and Health Administration.

The Human Factors specialists at Human Integration Ltd. are experienced in applying the many standards and guidelines that guide the design and application of signs and labels and can evaluate your present signage and labeling program and provide you with expert advice for improvement.

Musculoskeletal Risk

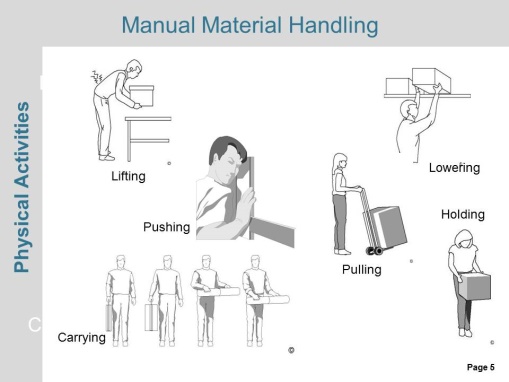

Designing to reduce physical injuries in a process plant involves study, analysis and application in two specialty areas – manual materials handling and Cumulative Trauma Disorders.Manual Material Handling injuries involve overexertion while lifting, lowering, pushing, pulling, carrying and holding. These tasks typically result in acute injuries (strains, sprains, tears or bruises). Lifting is considered the most “at risk” task because it involves each of the major joints associated with acute injuries.

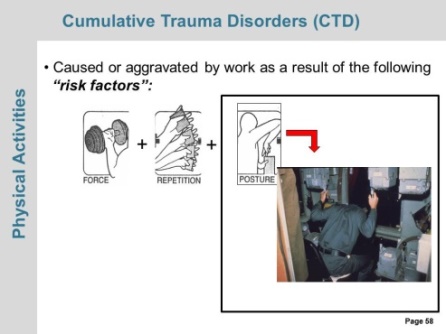

Cumulative Trauma Disorders, or CTDs, are the result of repeated micro-injuries to the soft tissues of the body (muscles, ligaments, tendons and nerves ) as a result of repetitive tasks that stress the tissues without giving them the opportunity to heal. The result is a full, debilitating injury.

Human Integration Ltd. personnel are specialists in the application of each of the tools that are used to analyze manual handling and cumulative trauma disorders and are expert in making recommendations to improve tasks that generate each type of disorder.